PolarOne Salt and Grit Spreaders

Welcome to PolarOne™, a market-leading, low-maintenance range of salt and grit spreaders designed to withstand the harshest of winter conditions. Manufactured at Wessex International’s UK headquarters, the PolarOne™ WS-900 and WS-1200 are perfect machines to complement demanding winter maintenance programmes, as they can spread both salt from their 900L and 1200L hoppers respectively, and liquid...

Product Description

Welcome to PolarOne™, a market-leading, low-maintenance range of salt and grit spreaders designed to withstand the harshest of winter conditions.

Manufactured at Wessex International’s UK headquarters, the PolarOne™ WS-900 and WS-1200 are perfect machines to complement demanding winter maintenance programmes, as they can spread both salt from their 900L and 1200L hoppers respectively, and liquid brine from the integral 465L tank.

The optional PolarOne™ COMMANDER

...Welcome to PolarOne™, a market-leading, low-maintenance range of salt and grit spreaders designed to withstand the harshest of winter conditions.

Manufactured at Wessex International’s UK headquarters, the PolarOne™ WS-900 and WS-1200 are perfect machines to complement demanding winter maintenance programmes, as they can spread both salt from their 900L and 1200L hoppers respectively, and liquid brine from the integral 465L tank.

The optional PolarOne™ COMMANDER live tracking system, for fleet and productivity management, provides realtime spreading data and application rates, essential for precise application and minimal material wastage.

The PolarOne™ vibration system is a patented auto vibration control to manage consistent material flow which is totally new and unique to the industry. Constructed with a weight-saving polypropylene hopper, and stainless steel anti-corrosion components, PolarOne™ is designed for longevity.

PolarOne™ can be trailer or vehicle-mounted and the list of key features and benefits is impressive.

THREE OPTIONS ARE AVAILABLE:

MODEL ST

A manually operated machine for those who want just a basic salt spreader, no speed control or data logging.

MODEL GT

All the functions of the standard machine but with the addition of GPS speed control where the system monitors changes in FWD speed and spread widths to maintain the requested application rate.

COMMANDER

All of the above with the addition of full telematics to provide a means to remotely monitor the salt spreader back at base. This set up would have access to a real-time webpage and open up a variety of additional facilities such as route logging, reporting and ring-fencing machines.

MULTIFUNCTIONAL IN-CAB CONTROLLER, SPECIFY YOUR DESIRED APPLICATION RATE THEN LET THE CONTROLLER DO THE WORK!

The GPS connectivity will adjust material delivery according to your vehicle speeds to maintain a consistent application rate. A speed optimisation indicator will help you optimise your driving speeds to improve the accuracy of spreading and productivity of your equipment and reduce material wastage.

Activate POLARFLO™ auto vibration system to provide consistent material feed onto the spinner or switch to manual mode to individually control auger & spinner speeds & also vibrators.

Read More- Features

- Specifications

- Manuals & Brochures

- Options

- POLYETHYLENE HOPPER AND INTEGRAL LIQUID TANK with self-supporting design for durability & weight saving.

- STAINLESS STEEL COMPONENTS & FIXINGS for corrosion resistance and longevity

- GPS CONTROLLED FLOW RATE FOR PRECISE APPLICATION and minimal material wastage increasing profitability.

- POLARFLO™ VIBRATION SYSTEM – Patented auto vibe control for consistent material flow

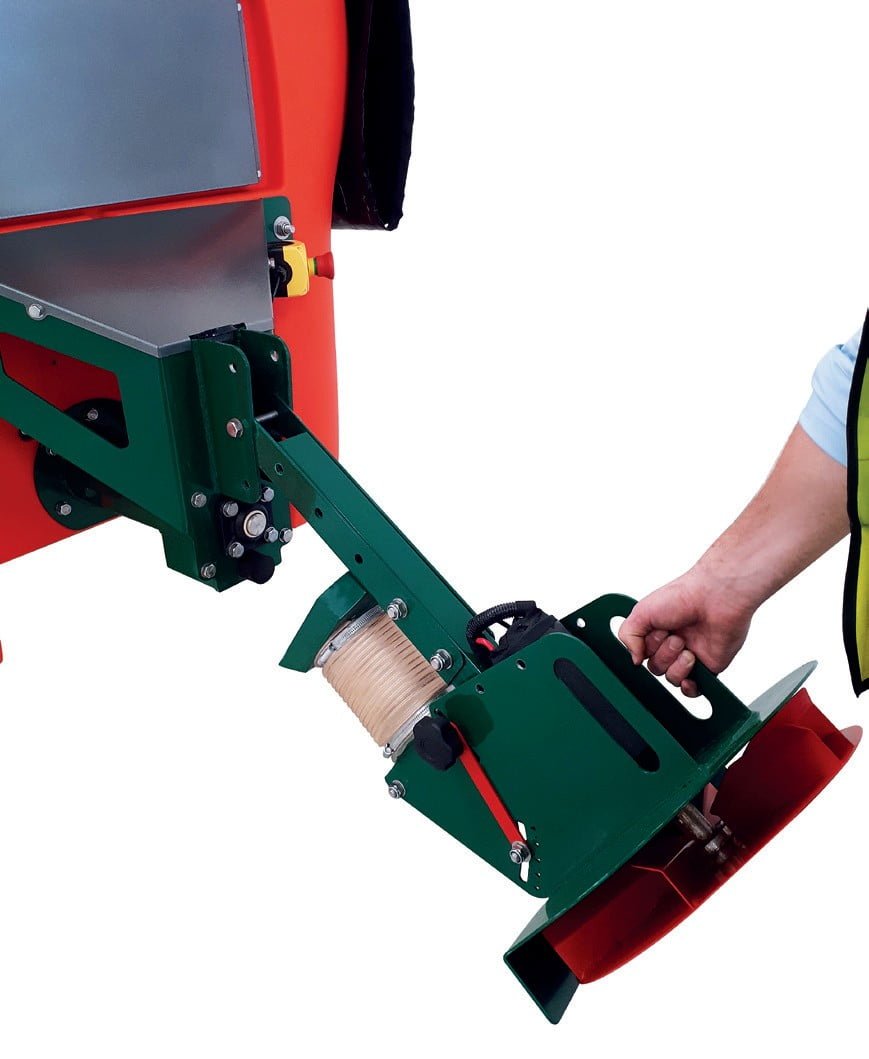

- ADJUSTABLE SPINNER HEIGHT WITH FOLD UP FEATURE – to suit a wide variety of vehicles

- EXTENDED AUGER DESIGN – allows better weight distribution in host vehicle

- NO ENGINES, BELTS, CHAINS OR GREASE POINTS – unique low maintenance design

- ADJUSTABLE CHUTE FOR AN OFFSET SPREADING PATTERN. Reducing the risk of overspread and increase output by treating two carriageways.

- LARGE DIAMETER AUGER WITH DELIVERY TUNNEL allows spreading of large range of materials, avoiding blockages and leakage.

- CAN BE TRAILER OR VEHICLE BED MOUNTED

POLARONE COMMANDER – LIVE TRACKING SYSTEM

- LIVE TRACK YOUR FLEET of spreaders

- QUICK ACCESS TO REAL TIME SPREADING DATA including application rates.

- EVIDENCE FOR YOUR CLIENT showing site visits and spreading data

WS-900 SALT & GRIT SPREADER

- Hopper capacity – Level (Litres) 900

- Hopper capacity – Rounded (Litres) 1000

- Spread width 1.5-10m

- Integral brine tank vol (L) 465

- Width (hopper only) 1140mm

- Height (hopper only) 1030mm

- Length (hopper only) 1820mm

- Bed length required 1750mm

- Auger diameter 105mm

- Weight empty 210kg

WS-1200 SALT & GRIT SPREADER

- Hopper capacity – Level (Litres) 1200

- Hopper capacity – Rounded (Litres) 1320

- Spread width 1.5-10m

- Integral brine tank vol (L) 550

- Width (hopper only) 1160mm

- Height (hopper only) 1030mm

- Length (hopper only) 2220mm

- Bed length required 2120mm

- Auger diameter 105mm

- Weight empty 230kg

MOUNTING PLATE FOR NUMBER PLATE & LIGHTING BOARD

WORKLIGHT

HIGHWAY TRAILER

Enquire Now

Please submit your request for a product demonstration, and we will call you back to arrange a suitable time.

"*" indicates required fields